Dried Food Products

MAP: A proven way to effectively extend the shelf life of your dried food products

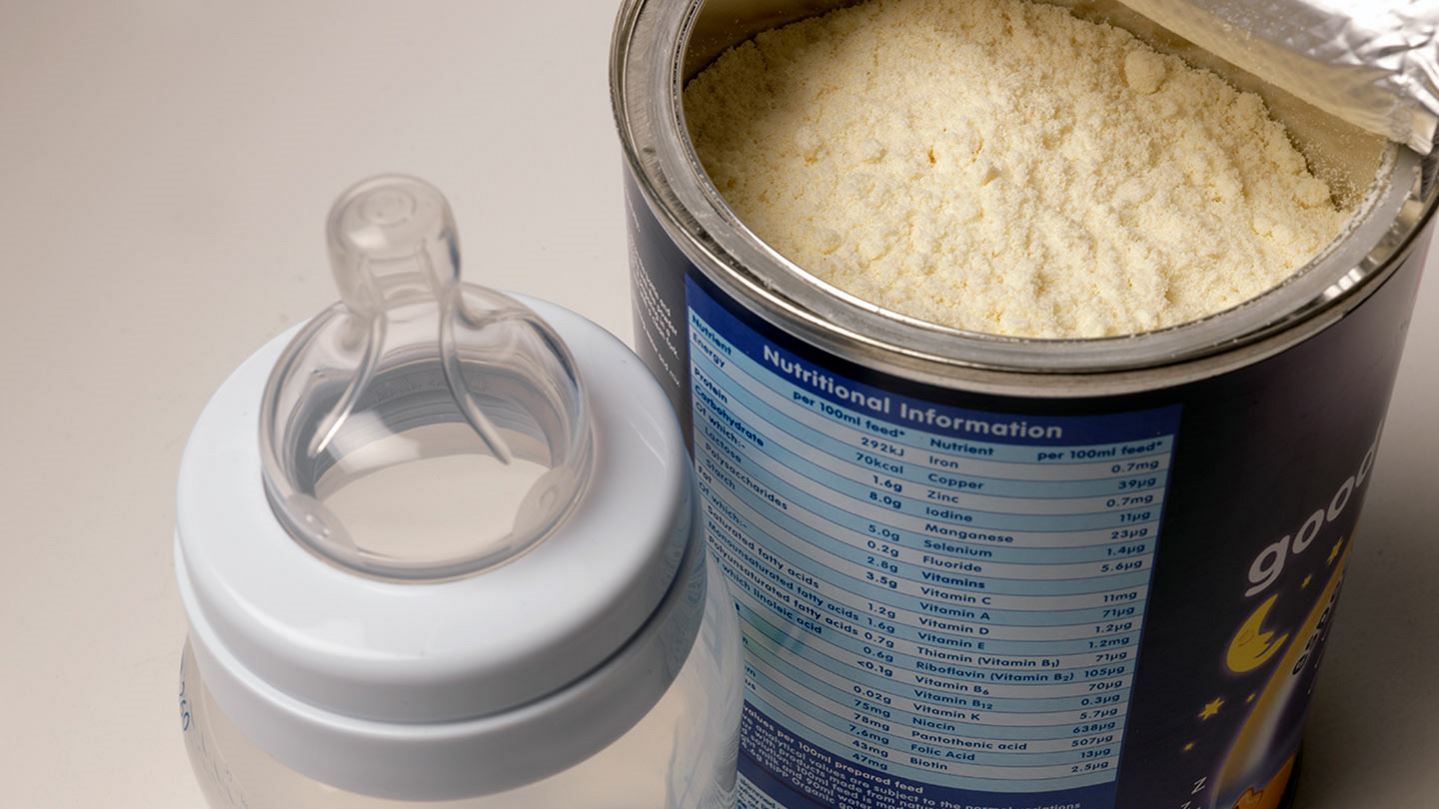

Food items: Cocoa Powders, Coffees, Dehydrated Milk, Dried and Salted Fish, Dried and Salted Seafood, Dried Beans, Dried Cereals, Dried Colourings, Dried Flavourings, Dried Fruits, Dried Herbs, Dried Lentils, Dried Mushrooms, Dried Pasta, Dried Snack Foods, Dried Spices, Dried Vegetables, Flours, Nuts, Potato Crisps, Teas, other items

Recommended gas mixture

100% N₂

The gases and mixtures listed above are for general guidance. To identify the optimum gas for your product and process, we recommend you undertake a product trial with the help of an Air Products MAP gas specialist.

Storage temperature

• Recommended: Ambient

Achievable shelf-life

• In air: 4-8 month

• In MAP: 1-2 years

Principle spoilage organisms and mechanics

Oxidative rancidity, Moisture loss or gain.

Food poisoning hazards include

Many food poisoning bacteria may survive on low aw dried foods. They will not grow on dried foods but may pose a possible food poisoning hazard upon reconstitution or when used as an ingredient in other high aw foods.

Typical MAP machines

Retail

TFFS – Thermoform-fill-seal

PTLF – Preformed tray and lidding film

HFFS – Horizontal form-fill-seal

VFFS – Vertical form-fill-seal

Typical types of package

Retail: Tray and lidding film, pillow pack

Examples of typical MAP materials

Tray:

• UPVC/PE

• HDPE

• EPS/EVOH/PE

Lidding and/or pillow pack film:

• PET/PVdC/PE

• PA/PVdC/PE

• PC/EVOH/EVA

• MPET

• MOPP

• OPP/PVdC

The principal spoilage mechanism affecting dried foods containing a high proportion of unsaturated fatty acids, such as cereals, potato crisps, nuts, cocoa powder and dried milk, is oxidative rancidity. This damaging reaction is very effectively inhibited by MAP in N₂. A gas/product ratio of 2:1 is often used. Due to the very long achievable shelf-lives in MAP for dried foods, MAP materials must have very high moisture and gas barrier properties. Metallised films possess these necessary properties. Certain dried foods, such as dried baby milk, are particularly susceptible to oxidative rancidity and residual O₂ levels should be below 0.2%.

In order to achieve very low residual O₂ levels, O₂ scavengers may be incorporated into MA packs. These O₂ scavengers may also be used for other low aw foods such as bakery products. The low aw of dried foods will prevent the growth of bacteria, yeasts and moulds. It should be noted, however, that many food poisoning bacteria may survive on dried foods, particularly herbs and spices, and may pose a hazard when subsequently reconstituted or used as an ingredient in high aw foods. Consequently, strict standards of hygiene and handling should be observed to minimise such food poisoning hazards.